Achieving a smooth finish is crucial in various industries, including printing, painting, and coatings. A film applicator is a versatile tool designed to help you achieve a uniform and even finish on different surfaces. In this article, we will delve into the world of film applicators, exploring their benefits, types, and applications.

What is a Film Applicator?

A film applicator is a device used to apply a thin layer of material, such as ink, paint, or coatings, onto a surface. It is commonly used in printing, painting, and coating industries to achieve a smooth and even finish. Film applicators can be manual or automatic, depending on the specific application and desired level of precision.

Benefits of Using a Film Applicator

Using a film applicator offers several benefits, including:

- Consistent finish: Film applicators ensure a uniform and even finish, reducing the risk of streaks, bubbles, and other imperfections.

- Time-saving: Automatic film applicators can significantly reduce the time and labor required to apply materials, increasing productivity and efficiency.

- Cost-effective: Film applicators can help reduce material waste and minimize the risk of errors, resulting in cost savings.

- Improved quality: Film applicators can help achieve high-quality finishes, meeting the demands of exacting industries such as aerospace and automotive.

Types of Film Applicators

There are several types of film applicators available, each designed for specific applications and industries. Some of the most common types include:

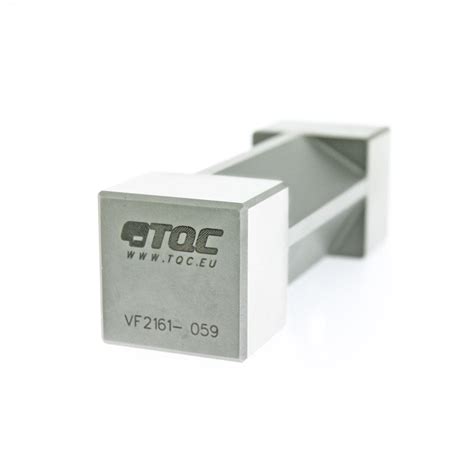

- Manual film applicators: These are handheld devices used for small-scale applications, such as applying coatings to small parts or prototypes.

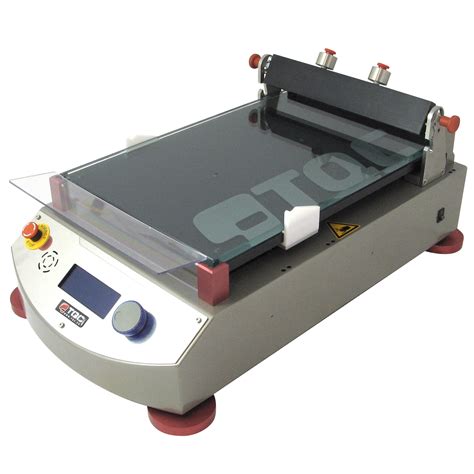

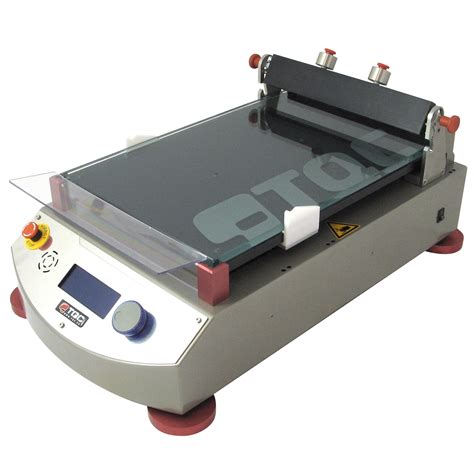

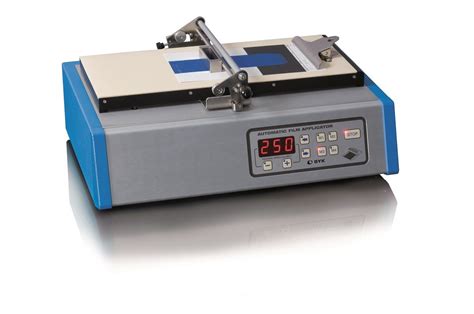

- Automatic film applicators: These are machine-based devices used for large-scale applications, such as applying coatings to large surfaces or production lines.

- Screen printing film applicators: These are specialized devices used for screen printing applications, such as applying ink to textiles or paper.

Applications of Film Applicators

Film applicators have a wide range of applications across various industries, including:

- Printing: Film applicators are used in printing applications, such as screen printing, flexography, and gravure printing.

- Painting: Film applicators are used in painting applications, such as applying coatings to metal, wood, and plastic surfaces.

- Coatings: Film applicators are used in coating applications, such as applying thin films to surfaces for protection, decoration, or functionality.

- Aerospace: Film applicators are used in aerospace applications, such as applying coatings to aircraft and spacecraft components.

How to Choose the Right Film Applicator

Choosing the right film applicator depends on several factors, including the specific application, material, and desired finish. Here are some tips to help you choose the right film applicator:

- Determine the material: Consider the type of material you will be applying, such as ink, paint, or coatings.

- Consider the surface: Consider the type of surface you will be applying the material to, such as metal, wood, or plastic.

- Choose the right size: Choose a film applicator that is the right size for your application, taking into account the surface area and material volume.

- Consider automation: Consider whether you need an automatic or manual film applicator, depending on the scale and complexity of your application.

Tips for Using a Film Applicator

Here are some tips for using a film applicator:

- Read the manual: Read the manual carefully before using the film applicator to ensure you understand its operation and settings.

- Calibrate the applicator: Calibrate the film applicator according to the manufacturer's instructions to ensure accurate and consistent results.

- Use the right material: Use the right material for your application, taking into account the surface and desired finish.

- Monitor the process: Monitor the process closely to ensure the material is being applied evenly and consistently.

Common Issues with Film Applicators

Here are some common issues that may arise when using a film applicator:

- Inconsistent finish: Inconsistent finish can occur due to incorrect calibration, material selection, or surface preparation.

- Material waste: Material waste can occur due to incorrect application or excessive material usage.

- Clogging: Clogging can occur due to incorrect material selection or poor maintenance.

Troubleshooting Film Applicators

Here are some troubleshooting tips for common issues with film applicators:

- Check the manual: Check the manual to ensure you are using the film applicator correctly.

- Clean the applicator: Clean the film applicator regularly to prevent clogging and material buildup.

- Adjust the settings: Adjust the settings to ensure the material is being applied correctly.

What is a film applicator?

+A film applicator is a device used to apply a thin layer of material, such as ink, paint, or coatings, onto a surface.

What are the benefits of using a film applicator?

+Using a film applicator offers several benefits, including consistent finish, time-saving, cost-effective, and improved quality.

What are the common issues with film applicators?

+Common issues with film applicators include inconsistent finish, material waste, and clogging.

We hope this guide has provided you with a comprehensive understanding of film applicators and their applications. Whether you are a professional in the printing, painting, or coatings industry, or simply looking for a smooth finish solution, a film applicator can be a valuable tool in your arsenal.