Industrial automation has revolutionized the way manufacturing processes are carried out in modern industries. The integration of automation technologies has significantly improved efficiency, productivity, and quality, while reducing costs and enhancing safety. In this article, we will explore the various applications of industrial automation in modern manufacturing and how it has transformed the industry.

What is Industrial Automation?

Industrial automation refers to the use of control systems, machinery, and software to automate industrial processes. It involves the integration of various technologies, such as robotics, computer systems, and sensor technologies, to create a fully automated manufacturing process. Industrial automation aims to improve the efficiency and accuracy of manufacturing processes, while reducing the need for human intervention.

Types of Industrial Automation

There are several types of industrial automation, including:

- Process Automation: This type of automation involves the control and monitoring of industrial processes, such as temperature, pressure, and flow rate.

- Discrete Automation: This type of automation involves the control and monitoring of individual products or parts, such as assembly lines.

- Batch Automation: This type of automation involves the control and monitoring of batch processes, such as mixing and blending.

Applications of Industrial Automation in Modern Manufacturing

Industrial automation has a wide range of applications in modern manufacturing, including:

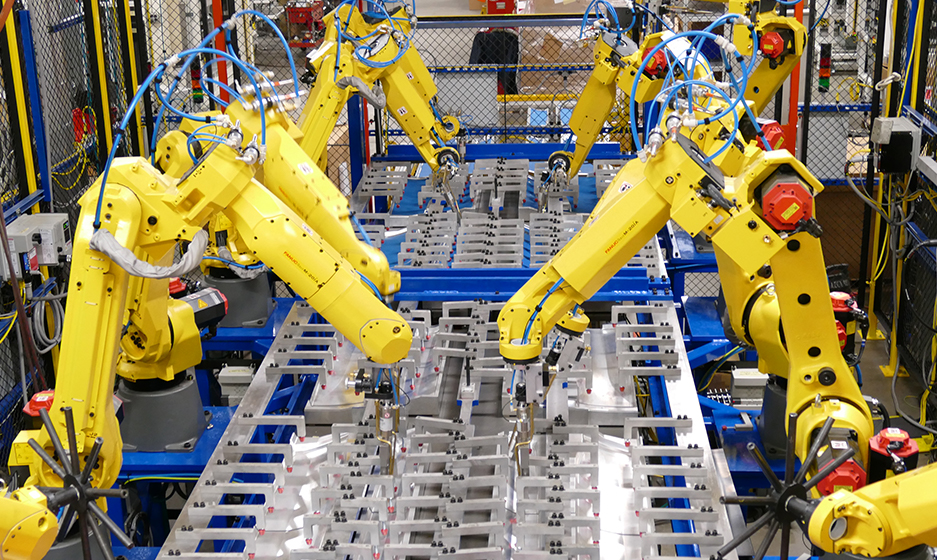

- Production Line Automation: Industrial automation is used to automate production lines, reducing the need for human labor and improving efficiency.

- Quality Control: Industrial automation is used to inspect and test products, ensuring that they meet quality standards.

- Inventory Management: Industrial automation is used to track inventory levels and automate ordering and restocking processes.

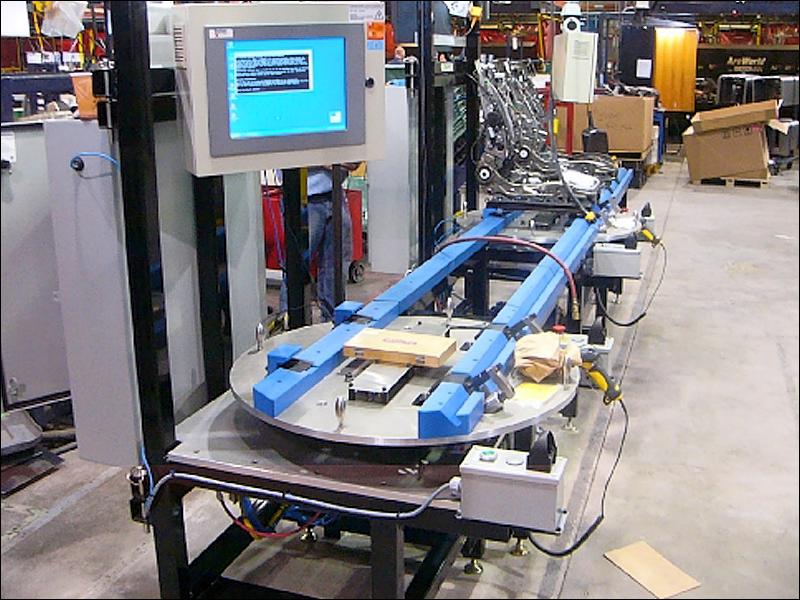

- Material Handling: Industrial automation is used to automate material handling processes, such as conveying and sorting.

- Packaging and Palletizing: Industrial automation is used to automate packaging and palletizing processes, reducing labor costs and improving efficiency.

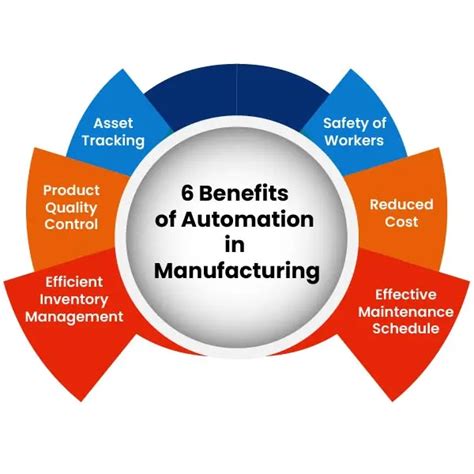

Benefits of Industrial Automation in Modern Manufacturing

The benefits of industrial automation in modern manufacturing include:

- Improved Efficiency: Industrial automation improves efficiency by automating processes and reducing the need for human labor.

- Increased Productivity: Industrial automation increases productivity by allowing for continuous operation and reducing downtime.

- Improved Quality: Industrial automation improves quality by ensuring that products meet quality standards.

- Reduced Costs: Industrial automation reduces costs by reducing labor costs and improving efficiency.

- Enhanced Safety: Industrial automation enhances safety by reducing the risk of accidents and injuries.

Challenges and Limitations of Industrial Automation

While industrial automation has many benefits, there are also challenges and limitations to consider, including:

- High Upfront Costs: Industrial automation requires significant upfront investment in equipment and software.

- Complexity: Industrial automation can be complex and require specialized knowledge and skills to implement and maintain.

- Cybersecurity Risks: Industrial automation systems can be vulnerable to cybersecurity risks, such as hacking and data breaches.

- Maintenance and Repair: Industrial automation systems require regular maintenance and repair to ensure optimal performance.

Future of Industrial Automation in Modern Manufacturing

The future of industrial automation in modern manufacturing is exciting and rapidly evolving. Emerging technologies, such as artificial intelligence and the Internet of Things (IoT), are expected to play a significant role in shaping the future of industrial automation.

- Artificial Intelligence: Artificial intelligence is expected to enable more advanced automation systems that can learn and adapt to changing conditions.

- Internet of Things (IoT): IoT is expected to enable greater connectivity and data exchange between devices and systems, enabling more efficient and effective automation.

Gallery of Industrial Automation Images

Frequently Asked Questions

What is industrial automation?

+Industrial automation refers to the use of control systems, machinery, and software to automate industrial processes.

What are the benefits of industrial automation?

+The benefits of industrial automation include improved efficiency, increased productivity, improved quality, reduced costs, and enhanced safety.

What are the challenges and limitations of industrial automation?

+The challenges and limitations of industrial automation include high upfront costs, complexity, cybersecurity risks, and maintenance and repair requirements.

As we conclude, industrial automation has revolutionized the way manufacturing processes are carried out in modern industries. Its applications in production line automation, quality control, inventory management, material handling, and packaging and palletizing have improved efficiency, productivity, and quality, while reducing costs and enhancing safety. While there are challenges and limitations to consider, the future of industrial automation is exciting and rapidly evolving, with emerging technologies like artificial intelligence and IoT expected to play a significant role.