The importance of efficient label application cannot be overstated in today's fast-paced manufacturing and production environments. Labels play a crucial role in product identification, enabling companies to quickly and accurately identify products, track inventory, and manage supply chains. However, traditional labeling methods can be time-consuming, labor-intensive, and prone to errors, leading to decreased productivity and increased costs.

In recent years, there has been a growing trend towards streamlining label application processes to improve efficiency, reduce waste, and enhance product identification. This shift has been driven by advances in technology, changing regulatory requirements, and the need for businesses to stay competitive in a rapidly evolving marketplace.

One of the key drivers of this trend is the increasing use of automation and robotics in label application. By leveraging automated labeling systems, companies can significantly reduce the time and labor required for labeling, while also improving accuracy and consistency. These systems can be programmed to apply labels quickly and precisely, minimizing the risk of human error and ensuring that products are correctly identified.

Another factor contributing to the streamlining of label application is the growing demand for sustainable and eco-friendly labeling solutions. As consumers become increasingly environmentally conscious, companies are seeking ways to reduce their carbon footprint and minimize waste. This has led to the development of innovative labeling materials and production methods that are more sustainable and environmentally friendly.

In addition to automation and sustainability, there is a growing trend towards standardization in label application. Standardized labeling processes and formats enable companies to simplify their labeling operations, reduce complexity, and improve consistency across different product lines and manufacturing sites. This, in turn, can help to reduce errors, improve product identification, and enhance overall efficiency.

The Benefits of Streamlined Label Application

The benefits of streamlined label application are numerous and far-reaching. Some of the most significant advantages include:

- Improved efficiency: Automated labeling systems and standardized processes can significantly reduce the time and labor required for labeling, freeing up resources for more critical tasks.

- Enhanced accuracy: Automated labeling systems can minimize the risk of human error, ensuring that products are correctly identified and reducing the risk of mislabeling.

- Increased productivity: Streamlined labeling processes can help to increase productivity, enabling companies to produce more products in less time and with greater accuracy.

- Reduced waste: Sustainable labeling materials and production methods can help to reduce waste and minimize environmental impact.

- Improved compliance: Standardized labeling processes and formats can help to ensure compliance with regulatory requirements, reducing the risk of non-compliance and associated penalties.

Implementing Streamlined Label Application

Implementing streamlined label application requires a strategic approach that takes into account a company's specific needs and requirements. Some of the key steps involved in implementing streamlined label application include:

- Assessing current labeling processes: Companies should assess their current labeling processes to identify areas for improvement and opportunities for streamlining.

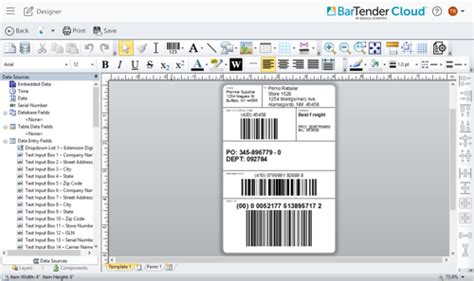

- Selecting the right labeling technology: Companies should select labeling technology that is tailored to their specific needs and requirements, such as automated labeling systems or sustainable labeling materials.

- Standardizing labeling processes: Companies should standardize their labeling processes and formats to simplify their labeling operations and improve consistency.

- Training staff: Companies should provide training to staff on new labeling processes and technology to ensure a smooth transition and minimize disruptions.

Best Practices for Streamlined Label Application

To achieve streamlined label application, companies should follow best practices that ensure efficient, accurate, and sustainable labeling. Some of the key best practices include:

- Using automated labeling systems to minimize manual labor and improve accuracy.

- Standardizing labeling processes and formats to simplify labeling operations and improve consistency.

- Using sustainable labeling materials and production methods to reduce waste and minimize environmental impact.

- Providing training to staff on new labeling processes and technology to ensure a smooth transition and minimize disruptions.

- Continuously monitoring and evaluating labeling processes to identify areas for improvement and opportunities for streamlining.

Common Challenges in Streamlined Label Application

While streamlined label application offers numerous benefits, there are also common challenges that companies may encounter. Some of the most significant challenges include:

- Initial investment costs: Implementing automated labeling systems and sustainable labeling materials can require significant upfront investment costs.

- Integration with existing systems: Streamlined labeling processes may require integration with existing systems, such as enterprise resource planning (ERP) software or product lifecycle management (PLM) systems.

- Training and support: Companies may need to provide training and support to staff to ensure a smooth transition to new labeling processes and technology.

- Regulatory compliance: Companies must ensure that their labeling processes comply with regulatory requirements, such as those related to product safety, environmental sustainability, and trade agreements.

What are the benefits of streamlined label application?

+The benefits of streamlined label application include improved efficiency, enhanced accuracy, increased productivity, reduced waste, and improved compliance.

How can companies implement streamlined label application?

+Companies can implement streamlined label application by assessing their current labeling processes, selecting the right labeling technology, standardizing labeling processes, and training staff.

What are some common challenges in streamlined label application?

+Some common challenges in streamlined label application include initial investment costs, integration with existing systems, training and support, and regulatory compliance.

We hope you've found this article informative and helpful in understanding the importance of streamlined label application. By implementing efficient and sustainable labeling processes, companies can improve productivity, reduce waste, and enhance product identification. If you have any further questions or would like to learn more about label application, please don't hesitate to contact us.