Nitrogen generators have become an essential tool in various industries, offering a reliable and cost-effective way to produce nitrogen gas on-site. The importance of nitrogen generators cannot be overstated, as they provide a convenient and efficient solution for industries that require a steady supply of nitrogen. In this article, we will explore the applications of nitrogen generators in various industries, highlighting their benefits and the reasons why they are a preferred choice for many businesses.

What are Nitrogen Generators?

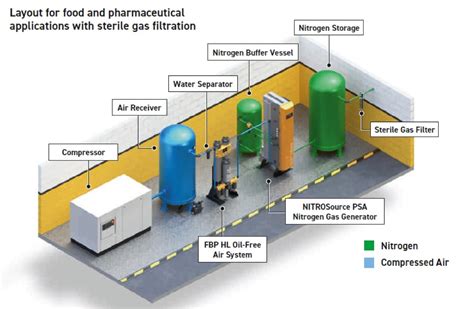

Before we dive into the applications of nitrogen generators, it's essential to understand what they are and how they work. Nitrogen generators are machines that produce nitrogen gas by separating it from the air we breathe. They use various technologies, such as pressure swing adsorption (PSA) or membrane separation, to extract nitrogen from the air and produce a high-purity gas.

Food and Beverage Industry

The food and beverage industry is one of the largest users of nitrogen generators. Nitrogen is used to preserve food by removing oxygen from packaging, which helps to prevent spoilage and extend shelf life. Nitrogen generators are used in various applications, including:

- Food packaging: Nitrogen is used to flush out oxygen from packaging, preventing the growth of bacteria and other microorganisms.

- Wine and beer production: Nitrogen is used to preserve wine and beer by removing oxygen from the packaging and preventing spoilage.

- Coffee production: Nitrogen is used to preserve coffee beans by removing oxygen from the packaging and preventing spoilage.

Benefits of Nitrogen Generators in the Food and Beverage Industry

- Cost-effective: Nitrogen generators provide a cost-effective solution for food and beverage manufacturers, as they eliminate the need for expensive nitrogen cylinders.

- Increased efficiency: Nitrogen generators provide a steady supply of nitrogen, reducing downtime and increasing efficiency.

- Improved product quality: Nitrogen generators help to preserve food and beverages by removing oxygen from packaging, extending shelf life and improving product quality.

Pharmaceutical Industry

The pharmaceutical industry is another significant user of nitrogen generators. Nitrogen is used in various applications, including:

- Drug packaging: Nitrogen is used to preserve drugs by removing oxygen from packaging and preventing spoilage.

- Laboratory applications: Nitrogen is used in laboratory applications, such as chromatography and spectroscopy.

- Medical equipment: Nitrogen is used in medical equipment, such as MRI machines and anesthesia systems.

Benefits of Nitrogen Generators in the Pharmaceutical Industry

- Improved product quality: Nitrogen generators help to preserve pharmaceutical products by removing oxygen from packaging, extending shelf life and improving product quality.

- Increased efficiency: Nitrogen generators provide a steady supply of nitrogen, reducing downtime and increasing efficiency.

- Cost-effective: Nitrogen generators provide a cost-effective solution for pharmaceutical manufacturers, as they eliminate the need for expensive nitrogen cylinders.

Aerospace Industry

The aerospace industry is also a significant user of nitrogen generators. Nitrogen is used in various applications, including:

- Tire inflation: Nitrogen is used to inflate tires, providing a safer and more reliable solution than compressed air.

- Leak testing: Nitrogen is used to test for leaks in aircraft and spacecraft.

- Purging: Nitrogen is used to purge oxygen from aircraft and spacecraft, preventing the risk of fire and explosion.

Benefits of Nitrogen Generators in the Aerospace Industry

- Improved safety: Nitrogen generators provide a safer solution for aerospace applications, as they eliminate the risk of fire and explosion associated with compressed air.

- Increased efficiency: Nitrogen generators provide a steady supply of nitrogen, reducing downtime and increasing efficiency.

- Cost-effective: Nitrogen generators provide a cost-effective solution for aerospace manufacturers, as they eliminate the need for expensive nitrogen cylinders.

Chemical Industry

The chemical industry is also a significant user of nitrogen generators. Nitrogen is used in various applications, including:

- Chemical synthesis: Nitrogen is used as a reactant in chemical synthesis reactions.

- Purging: Nitrogen is used to purge oxygen from chemical equipment, preventing the risk of fire and explosion.

- Storage: Nitrogen is used to store chemicals, preventing the growth of bacteria and other microorganisms.

Benefits of Nitrogen Generators in the Chemical Industry

- Improved product quality: Nitrogen generators help to preserve chemicals by removing oxygen from storage containers, extending shelf life and improving product quality.

- Increased efficiency: Nitrogen generators provide a steady supply of nitrogen, reducing downtime and increasing efficiency.

- Cost-effective: Nitrogen generators provide a cost-effective solution for chemical manufacturers, as they eliminate the need for expensive nitrogen cylinders.

What are the benefits of using a nitrogen generator?

+The benefits of using a nitrogen generator include cost-effectiveness, increased efficiency, and improved product quality.

What industries use nitrogen generators?

+Nitrogen generators are used in various industries, including food and beverage, pharmaceutical, aerospace, and chemical.

How do nitrogen generators work?

+Nitrogen generators work by separating nitrogen from the air we breathe, using various technologies such as pressure swing adsorption (PSA) or membrane separation.

In conclusion, nitrogen generators are a versatile and essential tool in various industries, offering a reliable and cost-effective solution for producing nitrogen gas on-site. By understanding the applications and benefits of nitrogen generators, businesses can make informed decisions about implementing this technology in their operations. Whether you're in the food and beverage, pharmaceutical, aerospace, or chemical industry, a nitrogen generator can help improve product quality, increase efficiency, and reduce costs.