The importance of accurate dispensing in various industries cannot be overstated. From healthcare and pharmaceuticals to cosmetics and food processing, the ability to precisely dispense liquids, gels, and other materials is crucial for ensuring product quality, safety, and efficacy. One tool that has revolutionized the dispensing process is the syringe applicator. In this article, we will delve into the world of syringe applicators, exploring their benefits, working mechanisms, and applications in different industries.

What is a Syringe Applicator?

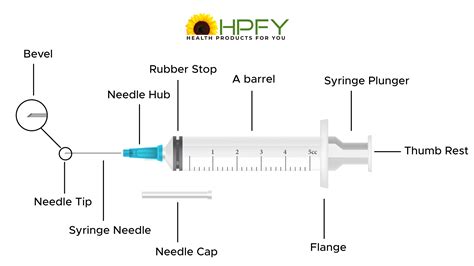

A syringe applicator is a device that uses a syringe-like mechanism to dispense a specific amount of material, such as a liquid, gel, or paste, onto a surface or into a container. The device typically consists of a cylindrical body, a plunger, and a dispensing tip. The plunger is used to push the material out of the syringe, while the dispensing tip controls the amount and direction of the dispensed material.

Benefits of Syringe Applicators

Syringe applicators offer several benefits that make them an essential tool in various industries. Some of the key advantages include:

- Accurate dispensing: Syringe applicators allow for precise control over the amount of material dispensed, reducing waste and ensuring consistent product quality.

- Easy to use: Syringe applicators are simple to operate, requiring minimal training and effort to dispense materials accurately.

- Versatility: Syringe applicators can be used with a wide range of materials, including liquids, gels, and pastes.

- Cleanliness: Syringe applicators are designed to minimize contamination, making them ideal for use in sterile environments.

Working Mechanism of Syringe Applicators

The working mechanism of a syringe applicator is relatively straightforward. Here's a step-by-step explanation of how it works:

- Loading the syringe: The syringe is loaded with the material to be dispensed.

- Setting the dispensing amount: The dispensing amount is set using the plunger or a built-in mechanism.

- Dispensing the material: The plunger is pushed, and the material is dispensed through the dispensing tip.

- Controlling the flow: The flow of material is controlled by the dispensing tip, which can be adjusted to achieve the desired dispensing pattern.

Applications of Syringe Applicators

Syringe applicators have a wide range of applications in various industries, including:

- Healthcare: Syringe applicators are used in healthcare to dispense medications, vaccines, and other medical materials.

- Pharmaceuticals: Syringe applicators are used in pharmaceutical manufacturing to dispense active ingredients and excipients.

- Cosmetics: Syringe applicators are used in cosmetics to dispense skincare products, such as creams and serums.

- Food processing: Syringe applicators are used in food processing to dispense ingredients, such as sauces and condiments.

Conclusion

In conclusion, syringe applicators are a valuable tool in various industries, offering accurate dispensing, ease of use, versatility, and cleanliness. Their working mechanism is straightforward, and they have a wide range of applications in healthcare, pharmaceuticals, cosmetics, and food processing. Whether you're a manufacturer, researcher, or healthcare professional, a syringe applicator can help you achieve precise dispensing and improve product quality.

What is a syringe applicator?

+A syringe applicator is a device that uses a syringe-like mechanism to dispense a specific amount of material, such as a liquid, gel, or paste, onto a surface or into a container.

What are the benefits of syringe applicators?

+Syringe applicators offer accurate dispensing, ease of use, versatility, and cleanliness, making them an essential tool in various industries.

What are the applications of syringe applicators?

+Syringe applicators have a wide range of applications in healthcare, pharmaceuticals, cosmetics, and food processing.